Human centered

Water ion air conditioner and water ion fan(Optional)

Smooth emergency terminal slowdown(SETS) technology(Optional)

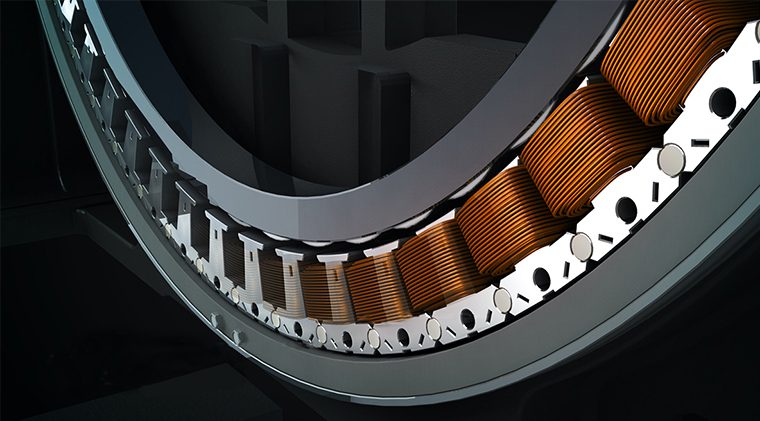

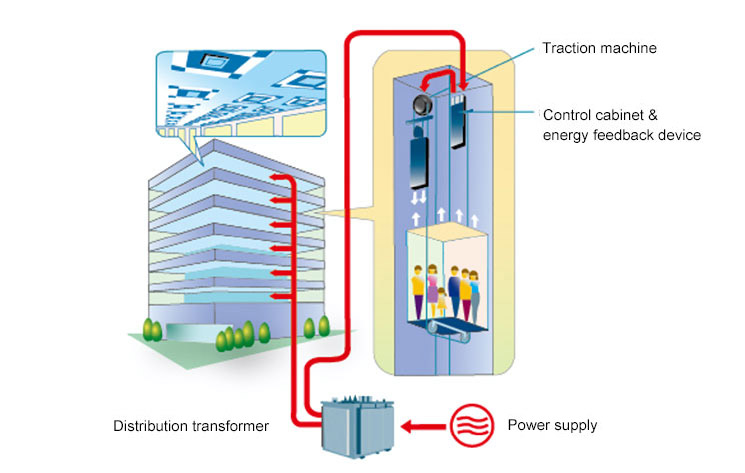

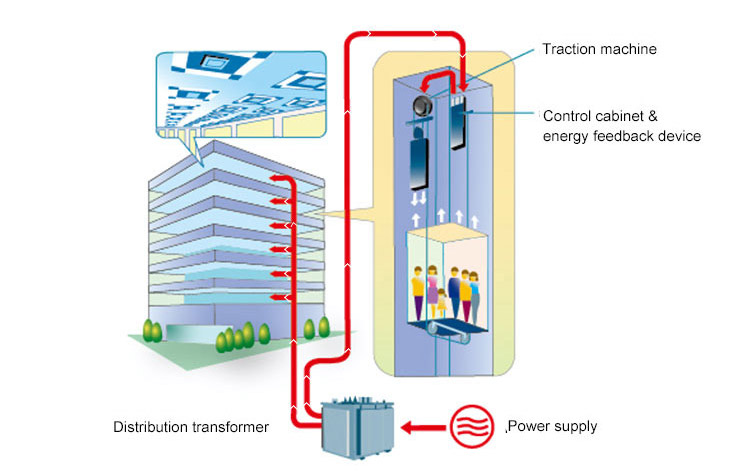

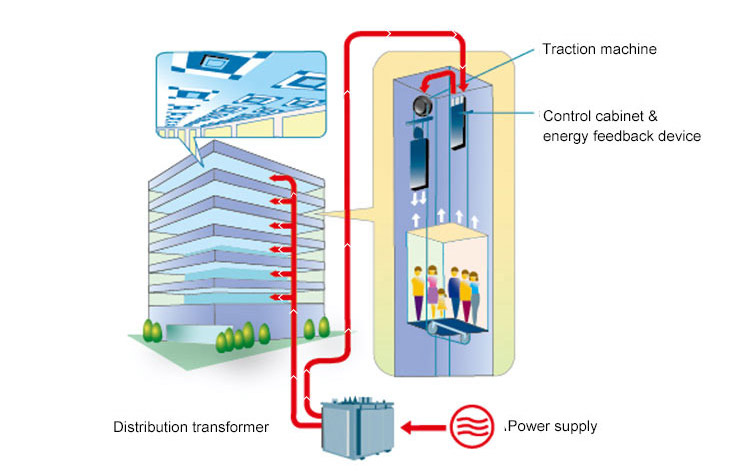

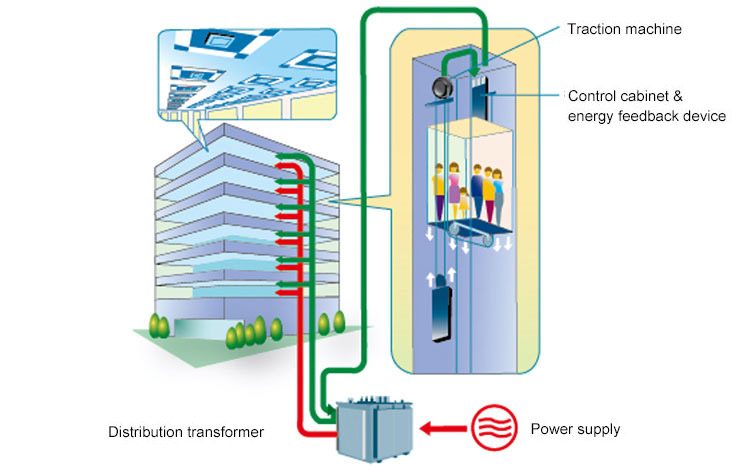

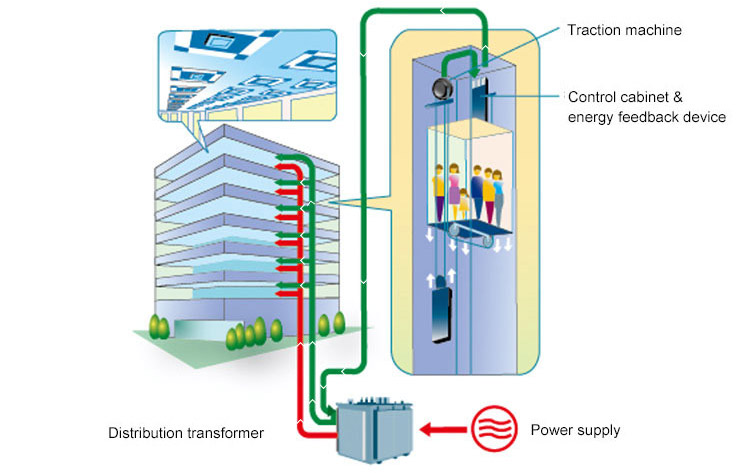

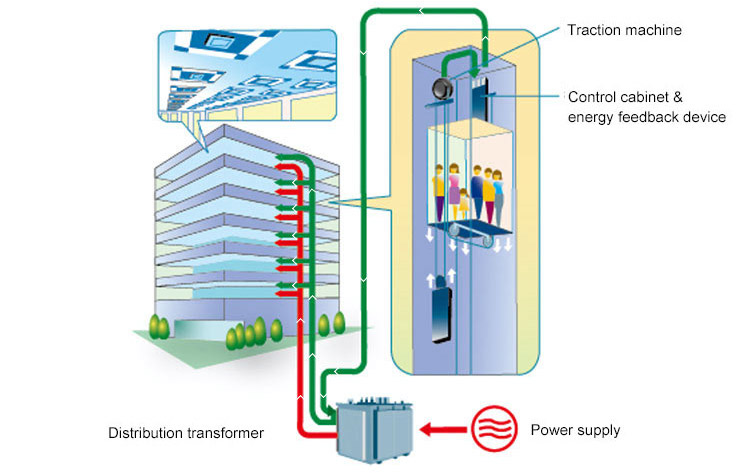

Energy feedback technology(Optional)

Elevator movement usually gains energy from power source (operation in electric mode); however, when it goes down under heavy load or goes up under light load (operation in power generation mode), the working state of traction machine is equivalent to power generator. In general, the energy generated by traction machine is dissipated in the form of heat energy. The energy feedback technology based on PWM control feeds the regenerative energy to the grid when the traction machine is in the power generation state, saving about 30% of energy compared with the elevator without energy feedback device, causing sinusoidal input current on the power supply side, and greatly reducing harmonic pollution to the power supply. Moreover, the DC side voltage is controlled, which contributes to improve the smoothness of elevator operation.

Fill in information

Please fill in the following relevant information, and our sales engineer will contact you to provide you with quotation scheme.

information

Welcome to scan the QR code to follow