2

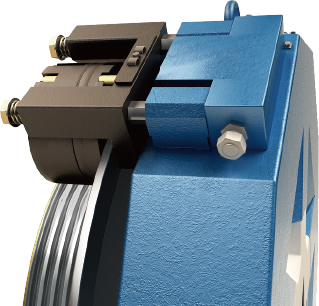

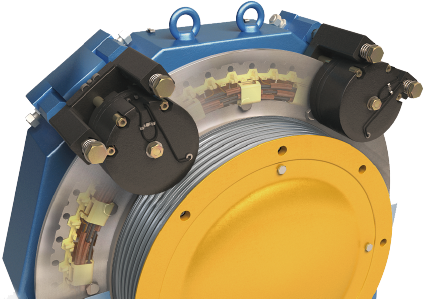

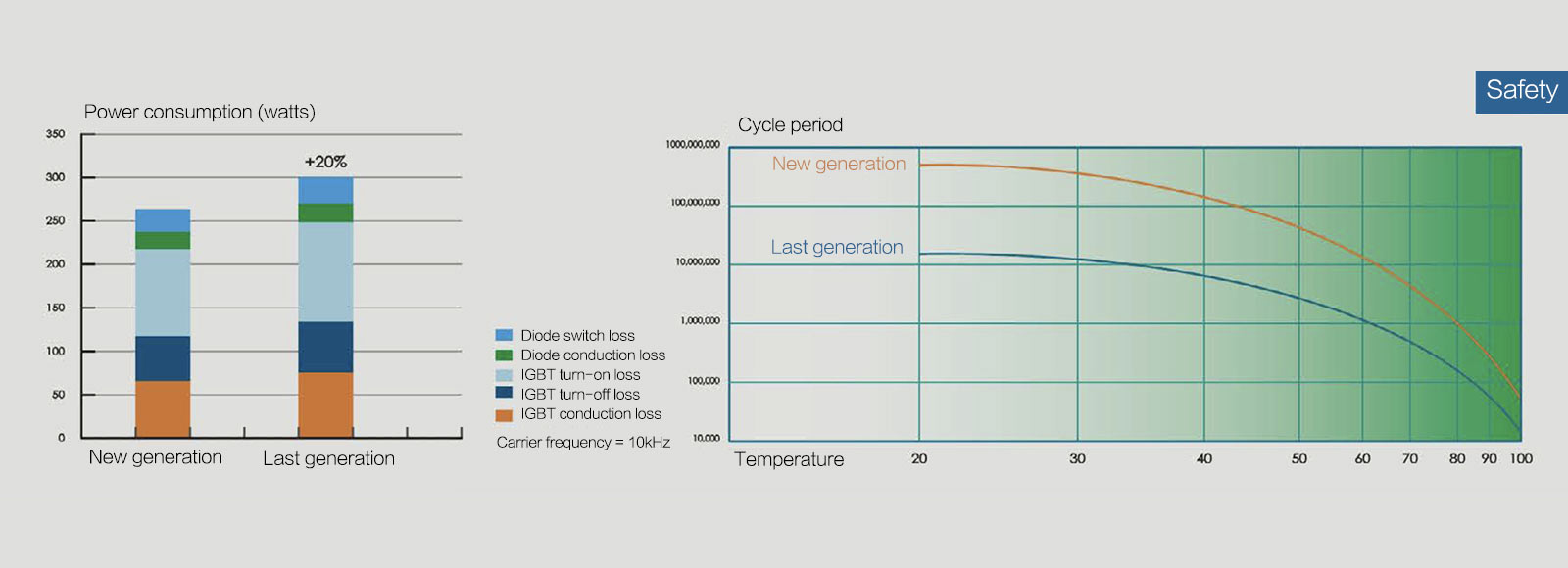

New upgrade of traction machine

Human centered

Water ion air conditioner and water ion fan(Optional)

The pictures are for demonstration only. Different size and view are possible. Any update or change of product or configuration is subject to real specification. To obtain accurate information, please contact SMEC's local branches.

TOP

Fill in information

Please fill in the following relevant information, and our sales engineer will contact you to provide you with quotation scheme.

Cancel

Submit

information

Cancel

Submit

Welcome to scan the QR code to follow

Founder of Comfort Elevator Technique

Founder of Comfort Elevator Technique