2

Innovative LEHY creation leads the way

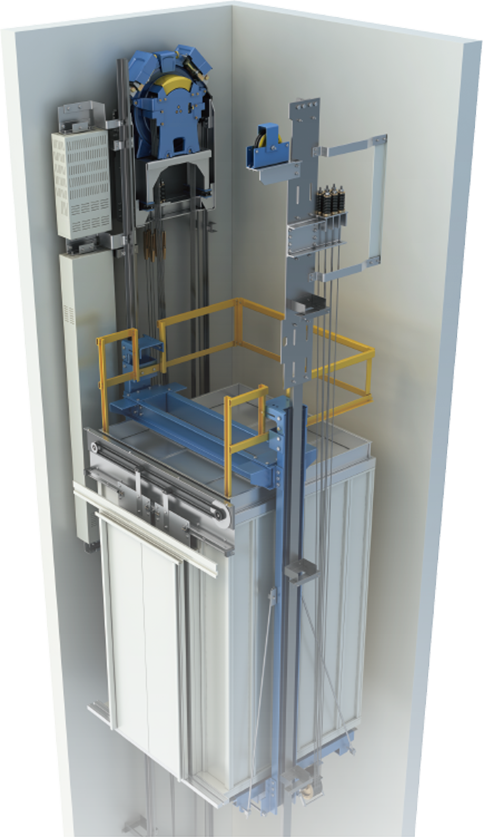

Slim design

-

Small control panel

Apply large-scale Field Programmable Gate Array (FPGA) and other high-performance chips to make the control panel small and slim

-

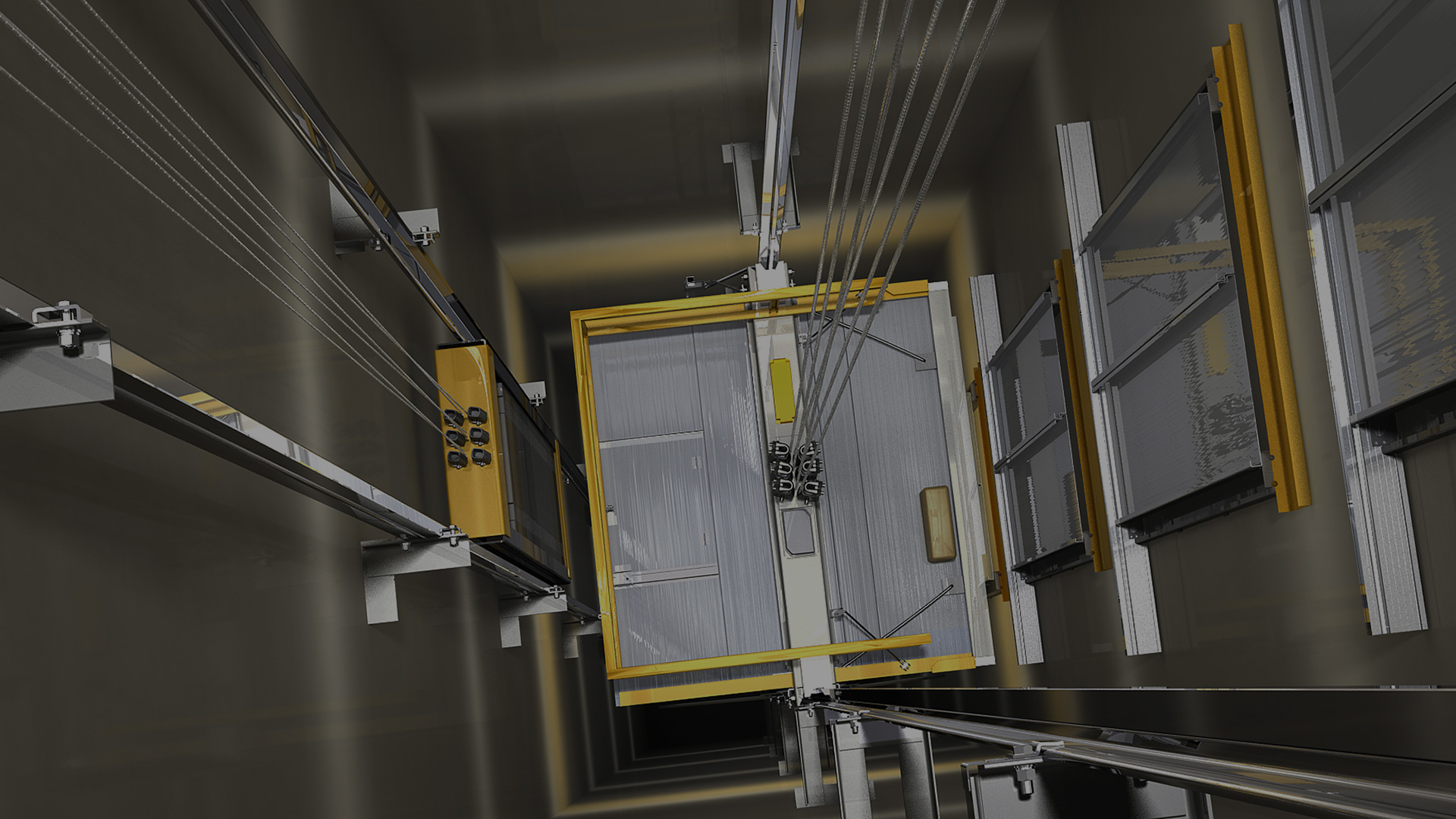

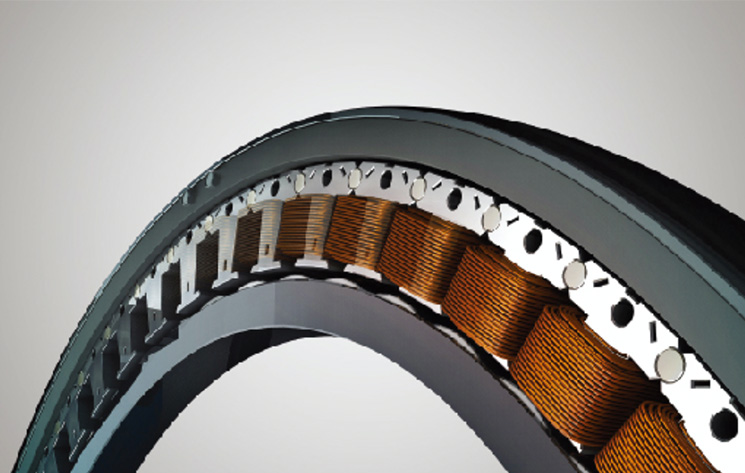

Superior PM Traction Machine

Elevators use Shanghai Mitsubishi’s latest technology

-

Ultra-slim PM Door Operator System

Use ultra-slim PM door operator with direct drive technology and speed-current double closed-loop VVVF technology

Usable space of car

Hoistway plane area Up to60.77%

-

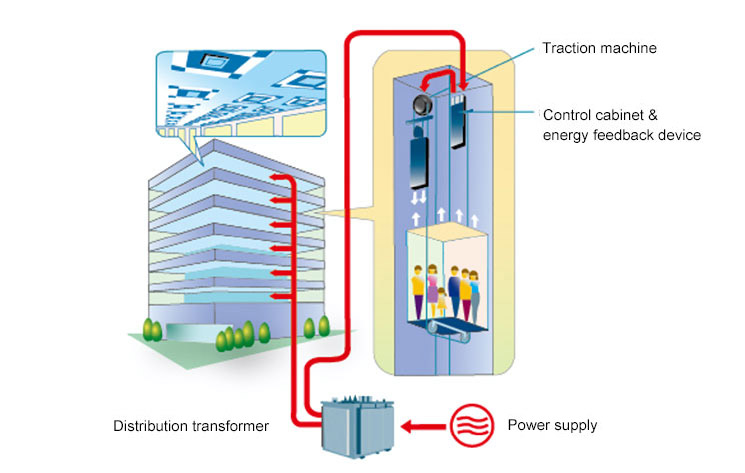

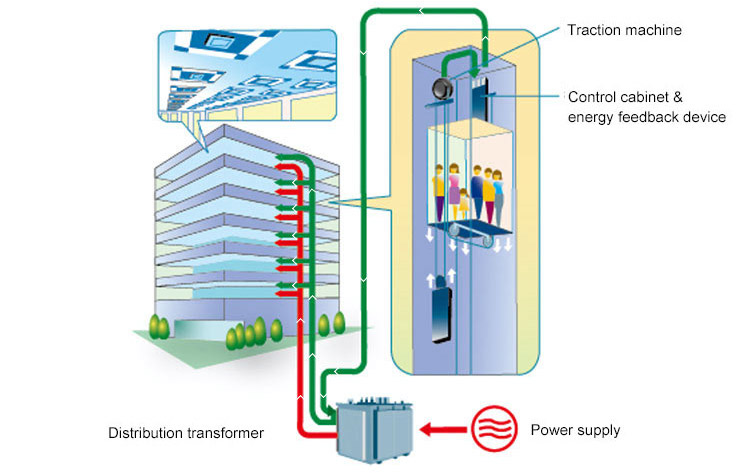

Make the best of energy

-

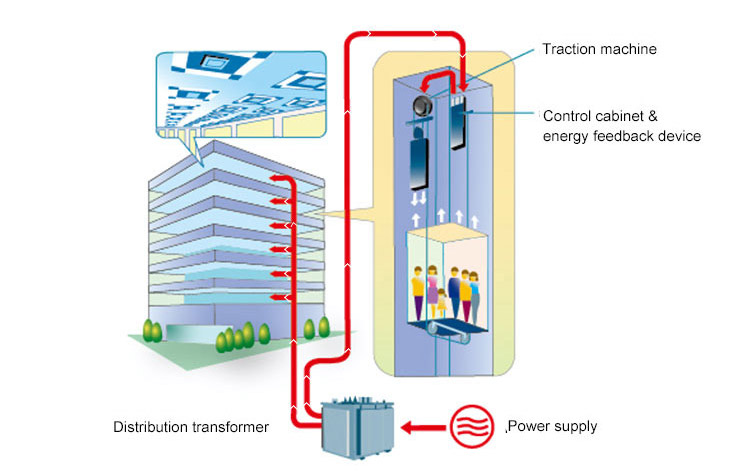

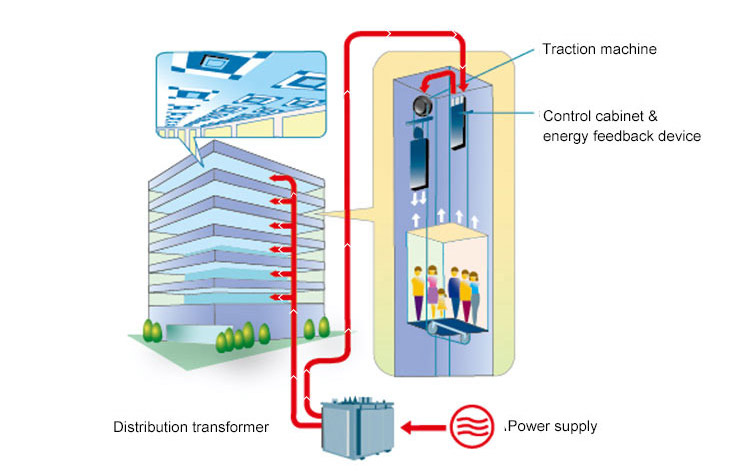

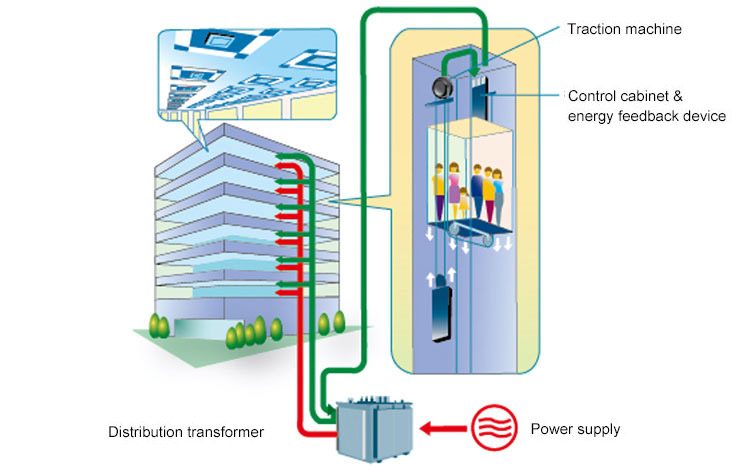

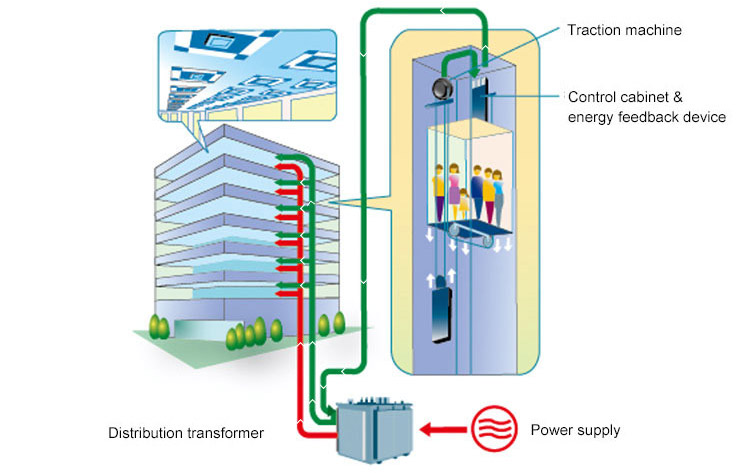

Power consumption and emission

Reduced by about70%

Energy feedback technology

-

Electric mode operation

-

Power generation mode operation

-

PM gearless traction technology

M gearless PM synchronous traction machine is made of permanent magnet materials, without additional excitation current, no copper loss, saving energy by about 30% compared with traditional worm gear traction machine,

-

Car Fan/Light shut off-automatic (CFO-A/CLO-A)

After the elevator has stood by without direction for a certain period of time, the car ventilation device/lighting is turned off automatically to save energy.

Fill in information

Please fill in the following relevant information, and our sales engineer will contact you to provide you with quotation scheme.

Cancel

Submit

information

Cancel

Submit

Welcome to scan the QR code to follow

Maintain Superiority and Nobility

Maintain Superiority and Nobility