Lead new trend of compact machine room elevator

Founder of comfort elevator technique

Founder of comfort elevator technique

Unparalleled comprehensive upgrade

Unparalleled comprehensive upgrade

Energy-efficient and environment friendly, last to the future

Energy-efficient and environment friendly, last to the future

Unprecedentedly comfort experience

Unprecedentedly comfort experience

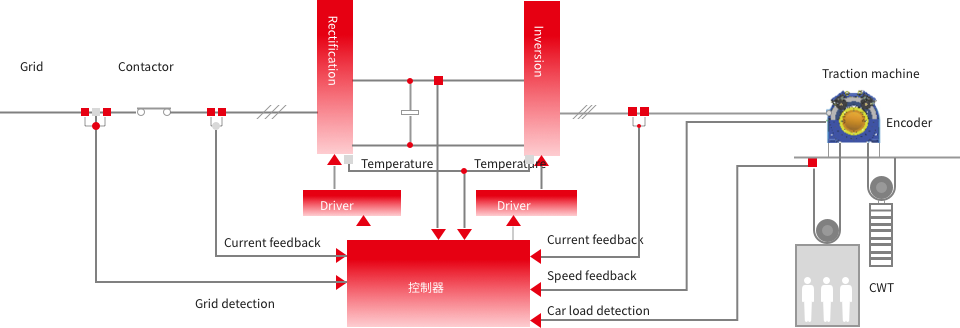

Adhering to the philosophy of steadily and slowing releasing of profound knowledge and constantly using latest technologies and components in VVVF drive of elevators enable Shanghai Mitsubishi VVVF speed regulation technology to develop rapidly toward high performance, high reliability, digitization and miniaturization. Employing space vector pulse width modulation (SVPWM) technology to realize elevator speed regulation, taking the lead in adopting international latest sixth generation of high-power module, 32-bit high speed digital signal controller (DSC) and large scale integrated circuit and other advanced electrical components, enabling the elevator to accurately regulate the motor rpm completely according to optimum speed variation curve and operate following the perfect speed curved optimized according to modern ergonomics principle. These have realized full digital control and motor drive in true sense and enabled the elevator run smoothly, safely and efficiently.

Adhering to the philosophy of steadily and slowing releasing of profound knowledge and constantly using latest technologies and components in VVVF drive of elevators enable Shanghai Mitsubishi VVVF speed regulation technology to develop rapidly toward high performance, high reliability, digitization and miniaturization. Employing space vector pulse width modulation (SVPWM) technology to realize elevator speed regulation, taking the lead in adopting international latest sixth generation of high-power module, 32-bit high speed digital signal controller (DSC) and large scale integrated circuit and other advanced electrical components, enabling the elevator to accurately regulate the motor rpm completely according to optimum speed variation curve and operate following the perfect speed curved optimized according to modern ergonomics principle. These have realized full digital control and motor drive in true sense and enabled the elevator run smoothly, safely and efficiently.

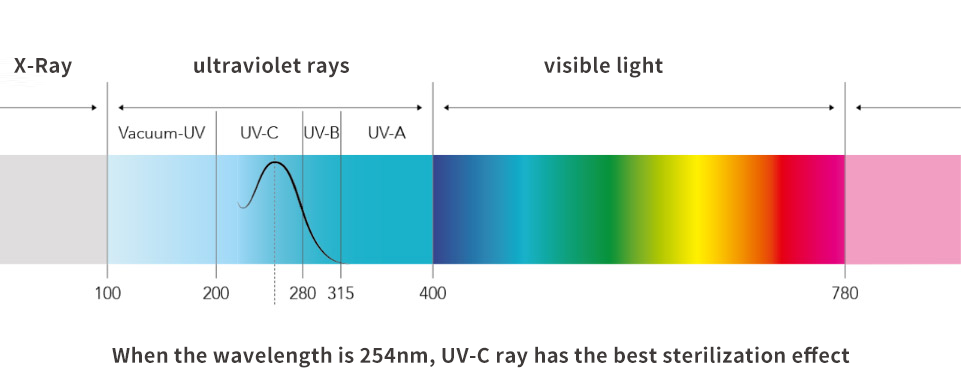

Highly energy-saving energy feedback technology based on dual-PWM control can feed the renewable green electric energy, which was consumed through energy consumption resistors, back to the grid without pollution. This can save more than 30% energy compared to common VVVF elevators on average, and so to meet relevant national power quality standards.

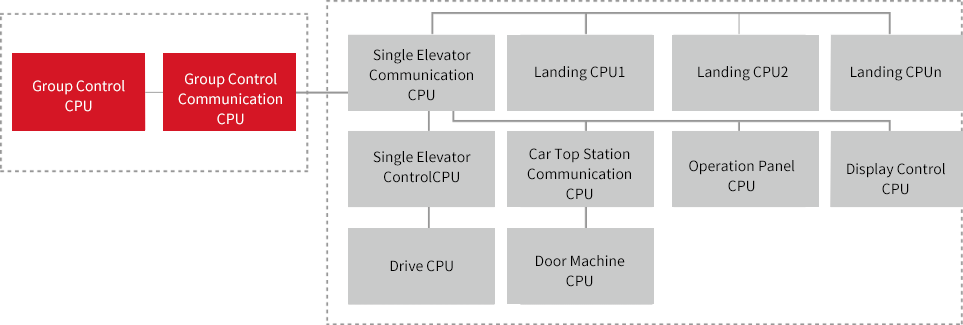

Data network control technology based on CANBUS (Field bus) features high communication rate, large data volume. Independent microprocessors are used separately in elevator car command controller, floor indicators inside the car, door machine controller, each landing button and floor indicators and various subsystems.

Data network control technology based on CANBUS (Field bus) features high communication rate, large data volume. Independent microprocessors are used separately in elevator car command controller, floor indicators inside the car, door machine controller, each landing button and floor indicators and various subsystems.

The communication between the various subsystems needs only a few signal lines. This has greatly improved system reliability, electromagnetic interference immunity and flexibility, and reduced the maintenance costs.

The communication between the various subsystems needs only a few signal lines. This has greatly improved system reliability, electromagnetic interference immunity and flexibility, and reduced the maintenance costs.

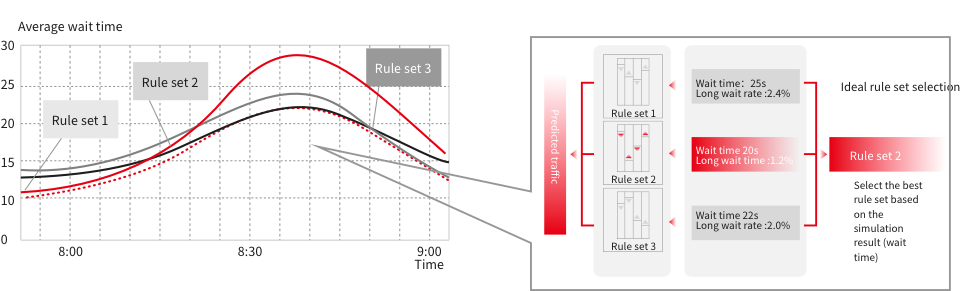

ITS-21, ITS-2100 group control systems use a high-performance CPU processor for computing and achieving high-speed processing of complex algorithms. High-speed data network has effectively improved the system throughput and scalability.

ITS-21, ITS-2100 group control systems use a high-performance CPU processor for computing and achieving high-speed processing of complex algorithms. High-speed data network has effectively improved the system throughput and scalability.

Expert system, fuzzy logic technology and neuron technologies are adopted. Dispatching plan can be given in an intelligent way according to different traffic conditions.

Expert system, fuzzy logic technology and neuron technologies are adopted. Dispatching plan can be given in an intelligent way according to different traffic conditions.

This can substantially reduce passengers’ waiting time and riding time and reduce elevator operation energy consumption throughout the building by reducing invalid elevator operation.

This can substantially reduce passengers’ waiting time and riding time and reduce elevator operation energy consumption throughout the building by reducing invalid elevator operation.

Greatly improve the utilization rate of elevators and reduce passengers’ average waiting time through the efficient destination force.

After a passenger has pressed the floor button he/she wish to go at the landing, the destination dispatch system will inform the passenger to take a specified elevator, and the passenger can then wait before the specified elevator.

After the elevator has arrived, the passenger does not need to press the button for the destination floor inside the car, and the elevator will automatically register and go to the destination floor.

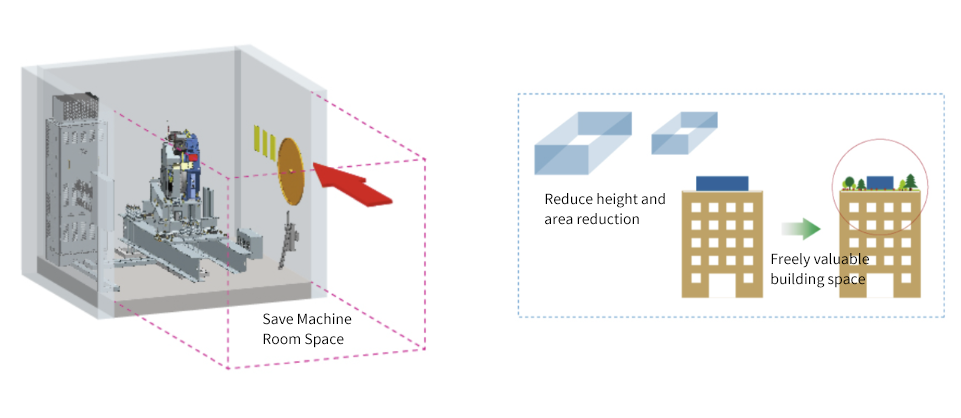

LEHY-III adopts really small machine room design with the machine room size equal to well. This saves machine room space, improves building utilization rate, allows more free building design, and compared to traditional machine room, provides more convenient and safe maintenance of the traction machine, control cabinet, over speed governor and other components.

沪公网安备31011202001781号

沪公网安备31011202001781号Please fill in the following relevant information, and our sales engineer will contact you to provide you with quotation scheme.